Introducing IaaS

WHIN's Innovation as a Service (IaaS) provides tailored solutions to manufacturing and agriculture businesses by leveraging advanced technology to enhance efficiency, productivity, and innovation. This service includes the integration of sensors, data analytics, and other smart technologies to optimize operations, improve decision-making, and drive digital transformation within these industries.

Who is WHIN?

We are a nonprofit focused on evaluating cutting edge technologies from around the world and bringing them to our region. We help local businesses and residents get access to cutting-edge tools. Our mission is to bridge the digital divide, support innovation, and boost economic growth. We aim to make our community thrive in the digital age.

How IaaS works

- Regional manufacturer has a problem which may require a specialized IoT solution.

- WHIN and manufacturer agree on the scope of the project.

- WHIN’s Innovation Team manages and implements the solution. WHIN may work with 3rd party partners during the project.

- Machine health monitoring

- Machine productivity monitoring (OEE, uptime, etc)

- Environmental condition monitoring

- Energy consumption monitoring

- Asset tracking and tracing

- And more!

Applications

BEARING FAILURE

A manufacturer has a bearing that infrequently fails, but when it does, long downtimes result. If rising bearing temperature could be detected before the failure, scheduled maintenance could occur, reducing unexpected downtime.

COMPLIANCE

A manufacturer desires real-time environmental monitoring, historical data, and alerts at various locations within their factory. This data (and the ability to take action on temperature-sensitive events) reduces waste and aids in regulatory compliance.

CRITICAL FAILURE

An electrical motor is attached to a critical asset on a manufacturer's shop floor. Having a sensor that can detect and alert maintenance staff to rising temperatures and out-of-tolerance vibrations prevents the motor from failing catastrophically and adjusting workloads while repairs are scheduled.

24/7 MONITORING

Staff periodically check a tank's level during working hours, but a manufacturer would like to have a sensor to alert them if the tank level falls outside of accepted levels on nights and weekends.

Share your needs with us, and Josh will reach out to explore how we can help!

IoT Demo Kit

The IoT Demo Kit is designed to enable a manufacturing company to experiment with a basic IoT solution within its facility prior to committing to a full Innovation-as-a-Service (IaaS) project with WHIN. The manufacturer and WHIN will select suitable sensors that address a specific pain point identified by the manufacturer. WHIN staff will provide any support needed to ensure a successful demo experience.

What you get in a demo kit

Sensors

- Temperature

- Vibration

- Humidity

- Amperage

Gateway

- Encrypted LoRaWAN network

- Cellular cloud gateway

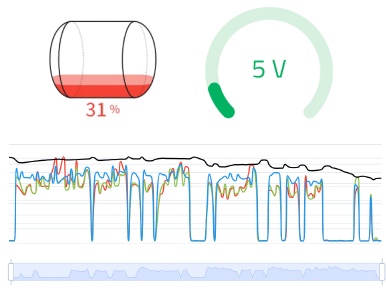

Online Dashboard

- Cloud-hosted dashboard

- Mobile text and/or email alerts

Share your needs with us, and Josh will reach out to explore how we can help!